2025-04-15 35

In recent years, with the increasing demand for efficient and reliable drive systems in various industries, as well as the use of new materials, permanent magnet motors (PM motors) have become more widely used and accepted by the market.And with the widespread use of permanent magnet motors, an innovative solution has emerged: the permanent magnet semi-direct drive system.This technology combines the advantages of permanent magnet motors with the characteristics of gearboxes to provide a powerful alternative to conventional drive systems.

What is a permanent magnet semi-direct drive system?

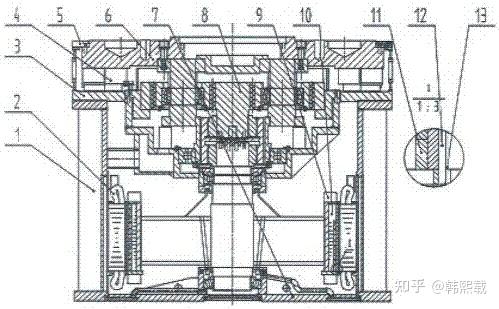

Permanent magnet semi-direct drive systems consist of two main components: a permanent magnet motor and a gearbox.Unlike direct drive systems, which eliminate the need for a gearbox by connecting the motor directly to the load, semi-direct drive systems utilize a gearbox to enhance performance characteristics.

The use of a gearbox results in enhanced torque output and better control of the motor's speed.This configuration is particularly effective in applications that require high torque at low speeds, such as heavy machinery, conveyor systems and electric vehicles.

1 . Improved Efficiency: With permanent magnet motors, the system is able to achieve higher efficiency than traditional induction motors.The permanent magnet motor reduces energy loss and promotes efficient operation of the overall system.

2 . Compact design: The combination of motor and gearbox achieves a more compact design, which is especially important in application scenarios where space is limited.The reduced size does not hinder performance, making it ideal for modern industrial applications.

3 . Improved Torque Characteristics: The gearbox enhances the torque output of the motor, improving performance in high-load applications.This is especially important in scenarios where high starting torque is required.

4 . Flexibility and Customization: Permanent magnet semi-direct drive systems can be customized to meet specific application requirements.By adjusting gear ratios and motor specifications, manufacturers are able to design systems that optimize performance to meet diverse operational needs.

Summarizing the application scenarios of permanent magnet semi-direct drive systems in recent years, we believe that the best application scenarios have the following characteristics:

1. Continuous operation: it is characterized by: more intuitive economic effect of energy saving; high requirements on the stability and easy maintenance of the transmission part.

2. Low-speed heavy-duty: Simple permanent magnet motors are too costly in low-speed heavy-duty scenarios because of the limitations of their torque density ratio ( motor torque density is the ratio of the motor's torque to the motor's total weight ), while the cost-effectiveness of permanent magnet semi-direct-drive systems is very high.

3. Intelligent control: through the frequency converter, more intelligent control requirements can be realized, which can improve the intelligent level of the plant and reduce labor costs to a certain extent.

Permanent magnet semi-direct drive systems represent a major advancement in drive technology, combining the benefits of permanent magnet motors with the efficiency of geared systems, and will play an important role in the future of a wide range of industries due to their compact design, superior efficiency and flexibility.As manufacturers continue to innovate, permanent magnet semi-direct drive systems may become the standard solution for high-performance applications.

As an important transmission device in the industrial field, micro gear reducer has a wide range of applications in various industries.According to the industry use, micro gear reducer can be divided into the following categories: military field: used in missiles, satellites and other precision equipment transmission system, requires high precision, high reliability and good anti-interference ability to ensure that the equipment in the complex battlefield environment can be stable operation.Automotive industry: For example, it is used in automobile electric seat adjustment, window lifting, wiper and other systems to help realize the precise motion control of these parts and enhance the comfort and safety of the car.Home appliance industry: Commonly used in washing machines, air-conditioners, ice creams, and other appliances.

The gearbox transmission system of large-scale heavy-duty equipment often works under complex working conditions such as heavy load, impact and variable load, and its core components are prone to damaging single and composite faults such as spalling, cracking and even fracture.Therefore, in-depth study of gear vibration mechanism, signal characteristics and fault diagnosis methods are of great significance.Recently, a research team launched a study on the coupling mechanism of compound faults in heavy-duty gearboxes under complex working conditions and multi-source excitation.They established a multi-degree-of-freedom coupled dynamics model of scalable gearbox with composite faults by using dynamic expansion and wavelet finite element and centralized parameter method as technical means, and studied the coupling factors and numerical solution algorithms as well as multi-degree-of-freedom coupled dynamics model of heavy-duty gearbox under complex working conditions with multiple sources.

In the heavy-duty gearbox industry, the right choice of gear oil is critical.Gear oils are like the lubricant between the joints of the human body, ensuring smooth power transmission and long-lasting durability of the components.Temperature is one of the key factors in selecting gear oils.At low temperatures, low viscosity lubricants flow well and reach all parts of the gear quickly, while at high temperatures, high viscosity oils prevent direct friction between the metals and provide better protection.The speed at which the gears are running should not be ignored.Low speed is suitable for the use of high viscosity oil, high speed is more appropriate to choose low viscosity oil, so as to ensure that the lubricant in a very short period of time into the gear gap.

Tel: 0523-87838908

E-mail: wusuoping@163.com

Add: No.1 Gensi Industrial Park, Taixing City, Jiangsu Province