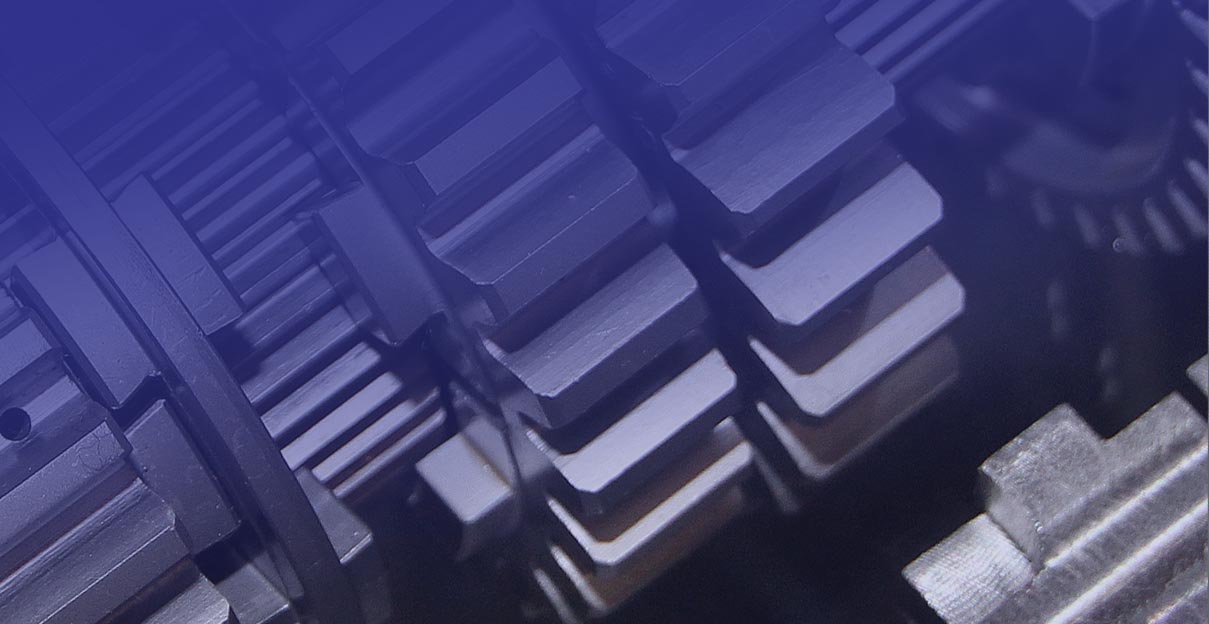

In recent years, with the development of material science and the advancement of motor technology, permanent magnet synchronous motors have been developing rapidly and have obvious advantages over traditional three-phase asynchronous motors.JSXX has followed the development trend of the transmission field, and has focused on the development of the PLANETPLUS ® Permanent Magnet Semi-Direct-Drive Transmission System through technological innovation and product iteration, from the traditional purely mechanical gear transmission.

The system uses high-performance permanent magnet materials, the application of deformation optimization design to improve the structure of the motor, as well as inverter DTC direct torque control and vector control, in the play of permanent magnet motor high efficiency and inverter control of intelligent advantages, while using the gear transmission structure of the high power density, effectively make up for the disadvantages of the relatively low torque density of the low-speed permanent magnet motors, with high efficiency, low loss, low noise, easy to maintain, High efficiency, low loss, low noise, easy maintenance, high reliability, high power density, providing customers with more cost-effective solutions.

We specialize in the production of high-quality gearboxes, especially in the field of permanent magnet semi-direct drive, and have established close cooperation with a number of well-known inverter and permanent magnet motor manufacturers. Through this efficient cooperation mechanism, we are able to realize integrated design to ensure the optimal performance and efficiency of our products. We emphasize the needs of our customers and help them to stand out from the competition with our quick response capability and flexible production process.